When it comes to electric vehicles (EVs), the Nissan Leaf stands out as one of the most popular models on the market—and at the heart of its evolution lies the changing technology of its battery modules. Recently, Art from GreenTec Auto gave an in-depth breakdown of how Nissan has changed their Leaf batteries over the years, the crucial differences between the various models, and how you can reuse these modules even after they’re no longer suited for driving. Let’s dive in!

Nissan Leaf Battery Modules: A History

- Gen 1 (2011–2012): 24 kWh Modules

The story starts with the earliest Nissan Leaf batteries—24 kWh packs launched in 2011 and 2012. Each module is rated at 500 watt-hours. A distinctive feature is a lip on the top, used for stacking orientation and indicating polarity (which alternates as you stack the modules). Nissan also used spacers—some with mounting bracket bolts and some without—to keep the 24-module stack together and secured. - Gen 2 (2013–2015): Smoother and Simplified

With the second generation, Nissan streamlined the design. The top lip was removed, leaving smooth sides that allowed the modules to be installed in any orientation (no more “left” or “right” sides). The spacer system was simplified with built-in metal brackets. Nissan also introduced a chemistry tweak intended to reduce heat-related degradation—but over time, it became clear that the real-world performance was nearly the same as Gen 1, with similar degradation rates. - 30 kWh (2016–2017): Higher Capacity, Major Problems

For the 2016 and 2017 models, Nissan rolled out 30 kWh packs. Each module is 1250 watt-hours, essentially two Gen 2 modules fused into one. To achieve this, Nissan removed the steel plate that used to separate the cells, which allowed for slightly larger cells and higher capacity. Unfortunately, these packs suffered from severe degradation, and Nissan issued a recall. If you still have a 30 kWh pack original to your car, you’re eligible for a free upgrade to a 40 kWh pack—though wait times can vary. - 40 kWh (2018+): Improved Reliability

The 40 kWh module proved far more durable. Each is 1670 watt-hours, physically the same size as the 30 kWh modules but with improved chemistry and energy density. The design retained the double-stack cell layout and bracket system but with much better long-term reliability than the problematic 30 kWh packs. - 62 kWh (2019+): Bigger, Denser, More Complex

Starting in 2019, Nissan offered the 62 kWh pack as an option alongside the 40 kWh. These packs use three different module types to maximize energy storage in the available space:

- 4S 3P – 2589 watt-hours

- 7S 3P – 4531 watt-hours

- 9S 3P – 5826 watt-hours

There are four tall modules, four medium modules, and eight smaller ones, arranged to fit the pack as tightly as possible. Unlike earlier designs that paired two cells in parallel, these newer modules use three cells in parallel, increasing energy density. However, this also makes them harder and more expensive to repair—if one cell fails, a much larger portion of the module is lost. The 62 kWh pack is also slightly taller and larger overall compared to the earlier packs.

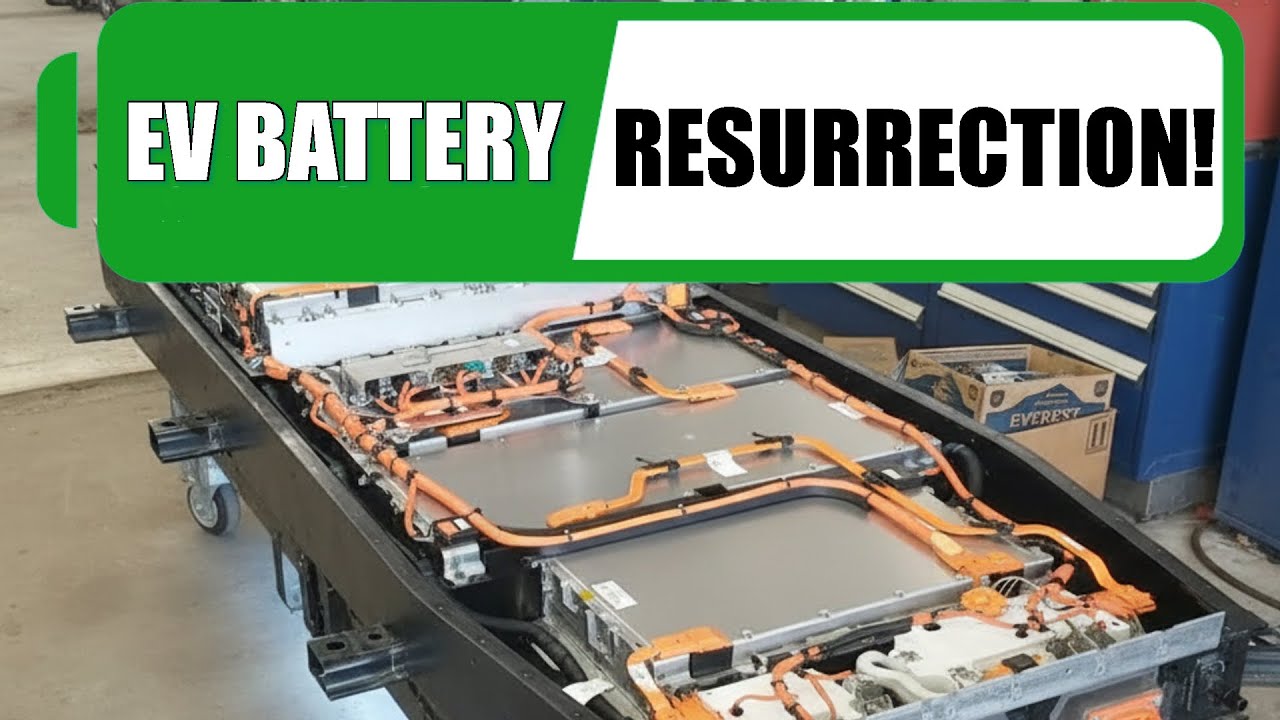

What Happens When These Batteries Leave the Road?

Even after their automotive life, Nissan Leaf modules still hold plenty of usable energy. While they may no longer handle the high current loads required in a vehicle, they perform exceptionally well in lower-current applications such as solar energy storage or golf carts.

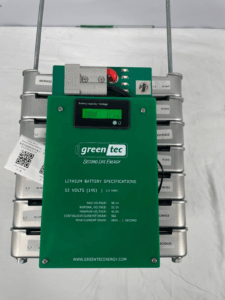

Enter the BMS: Making Modules Work for You

To repurpose Leaf modules, GreenTech Auto has developed custom Battery Management System (BMS) kits designed for different applications:

- 14S 50A BMS – Ideal for standard setups.

- 14S 100A BMS – Designed for higher-current uses, such as golf carts.

- 12S 50A BMS – Built for 30 kWh and 40 kWh modules, where it’s harder to collect seven modules for a 14S setup. This version is also backward compatible with Gen 1 and Gen 2 modules.

These BMS kits feature Bluetooth connectivity, allowing users to monitor voltage, temperature, and battery health directly from their phones. Multiple systems can be paralleled together for additional range, and advanced users can even share a middle module across two 14S setups for creative configurations.

For the 62 kWh modules, no dedicated BMS kits are currently available. That’s partly because these packs are still relatively new and most are still in vehicles. Another reason is that the 62 kWh modules are easier to connect in series—using simple wires with ring terminals instead of custom jumpers, unlike earlier generations.

Key Differences Between the Modules

- Physical Design: From Gen 1 lips and spacers → Gen 2 smooth-sided design → larger, multi-stack modules.

- Chemistry: Incremental tweaks across generations; major reliability improvements starting with the 40 kWh.

- Capacity & Format: Grew from 500 Wh per module to nearly 6,000 Wh in the 9S 3P modules.

- Repairability: Earlier modules were easier and cheaper to fix; newer, larger modules are denser but less repairable.

Real-World Uses for Old EV Modules

Nissan Leaf batteries may retire from vehicles, but they continue to shine in second-life applications:

- Home solar storage: Capture and store solar power for nighttime use.

- Golf cart upgrades: Paired with higher-current BMS kits for extra performance.

- Off-grid power systems: A dependable option for remote or backup energy.

With smart reconfiguration and the right BMS, Nissan Leaf modules of all generations can enjoy a productive second act.

As EV technologies continue to evolve, opportunities for reusing these batteries will only expand. Whether for solar, golf carts, or custom projects, second-life Leaf modules still have plenty to give.

Want to learn more or request a custom BMS configuration? Visit GreenTech Auto and share your ideas in the comments for future videos!

Real-World Uses for Nissan Leaf Modules

Even after they’ve reached the end of their service life in a vehicle, Nissan Leaf battery modules remain highly valuable for second-life applications. Their durability, energy density, and relatively compact form factor make them one of the most popular choices for DIY builders, renewable energy enthusiasts, and small businesses looking to tap into affordable lithium-ion storage. Here are some of the most practical and proven uses for Nissan Leaf modules:

- Home Energy Storage Systems

Nissan Leaf modules can be reconfigured into stationary battery banks that store excess electricity generated by the grid or other sources. Many homeowners use them in home energy storage systems to reduce utility costs, provide backup power during outages, and smooth out energy usage during peak hours. When paired with an inverter and BMS, Leaf modules offer a safe and scalable way to build custom storage systems that rival commercial solutions at a fraction of the cost. - Home Solar Battery Storage

For those with rooftop solar, Leaf modules are particularly valuable. Since solar panels only generate power during daylight, a storage system ensures that electricity can be used in the evenings or on cloudy days. By integrating Nissan Leaf modules with a solar array, homeowners can increase energy independence, reduce reliance on the grid, and make the most of renewable generation. This is one of the fastest-growing second-life applications for Leaf batteries. - Golf Cart Upgrades

Leaf modules also shine in golf cart and low-speed vehicle upgrades. Replacing traditional lead-acid batteries with Leaf lithium-ion modules not only reduces weight but also increases range, efficiency, and lifespan. With the right BMS kit—such as the 100A option GreenTech offers—these modules can safely deliver the higher currents golf carts require, making them a popular choice for both recreational and commercial fleets. - Off-Grid Power Systems

In cabins, workshops, or remote locations, off-grid users have embraced Nissan Leaf modules as reliable energy storage. Their compact design and ability to be stacked in series or parallel allow for highly customizable systems. Whether powering appliances, lighting, or small industrial equipment, Leaf modules provide dependable storage capacity without the cost of brand-new lithium-ion batteries. - EV Conversions

Another innovative application is electric vehicle conversions. Builders often turn to Nissan Leaf modules as a cost-effective way to electrify classic cars, motorcycles, or small utility vehicles. Their modular structure allows them to be configured into packs of varying voltages and capacities, making them adaptable for a wide range of EV projects. While newer modules may be harder to repair, their higher energy density provides exceptional performance for conversion builds.

In short, Nissan Leaf modules continue to deliver real value long after their original automotive life. From powering homes and solar arrays to enhancing mobility and enabling EV conversions, their second-life applications are expanding rapidly as more packs enter the aftermarket. This versatility, combined with proven BMS solutions, makes Nissan Leaf modules one of the best candidates for repurposing in today’s growing renewable energy and electrification space.